Use

-

Basics (Click for more)

- Publications

- Technotes

- Videos

-

Literature

- Links

Biodiesel Benefits

- Renewable

- Higher Cetane Number

- Cleaner Burning

- Nontoxic

- Environmentally Friendly

- Domestic

- More Food

- Adds to Fuel Lubricity

- Interchangeability

Renewability of a biofuel is measured as a ratio of units of energy in fuel to units of non-renewable energy used to produce it. Biodiesel has this ratio 5.5:1. To learn more, click here.

The cetane number is an indication of a fuel’s readiness to autoignite after it has been injected into the diesel engine. Diesel fuel for use in on-highway engines is required to have a cetane number of 40 or higher. Since higher cetane number translates into higher fuel cost, most refiners keep the cetane number of their diesel fuels between 40 and 45.

For biodiesel the cetane numbers are generally between 46 and 60 depending on the feedstocks used to make the biodiesel. Methyl esters tend to be slightly below ethyl and higher esters. Biodiesel from saturated feedstocks such as animal fat and recycled restaurant greases will be higher than the esters of oils high in polyunsaturates such as soybean oil.

The usual effect of a high cetane number is to shorten the ignition delay period between when the diesel fuel is injected and when it actually ignites. With conventional diesel fuel, the effect of shortening this period is to decrease the amount of fuel that is prepared to burn so that when autoignition actually occurs, the combustion event will be less severe. This results in a lower rate of pressure rise and less engine noise. To learn more, click here or look into our collection of literature about the cetane number.

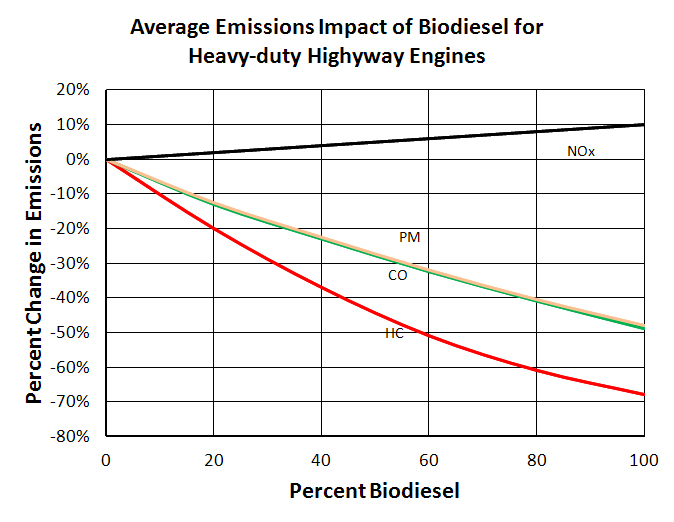

Biodiesel emissions are significantly lower compared to diesel fuel (except for NOx). The figure below shows the average emission of using biodiesel in heavy duty truck on engines made prior to 2007 EPA standard. These emissions were measured by EPA under "Biodiesel Emission Analysis Program" in 2002.

Research on a newer engine showed a lower Nox emission. Research on an alternative NOx reduction system called a NOx adsorber catalyst (NAC) demonstrated increased NOx conversion for biodiesel because biodiesel leads to reduced exhaust temperature. The lower operation temperature for the NAC increased the amount of NOx adsorbed and subsequently higher NOx reduction was achieved. The average tailpipe results operating the vehicle on B20 were in the range of 0.03 g/mi, while the emissions with ultra low sulfer diesel (ULSD) averaged below 0.05 g/mi with larger cycle-to-cycle variability (source: McCormick. 2016. Biodiesel Performance with Modern Engines and Taur et al. 2008.Effects of Biodiesel Operation on Light-Duty Tier 2 Engine and Emission Control Systems). For more please look into our collection of literature about the NOx emissions.

Biodiesel is less toxic than table salt. There are several studies evaluating biodiesel and diesel toxicity in terresterial and aquatic animals. Please look into our collection of literature about biodiesel toxicity

Use of biodiesel instead of regular diesel reduces greenhouse gas emissions over 80%. A biofuel that reduces greenhouse gas emissions by 50% or more is called advanced biofuel. Biodiesel is the only commercially available advanced biofuel today. To learn more, click here or look into our collection of literature about cetane number.

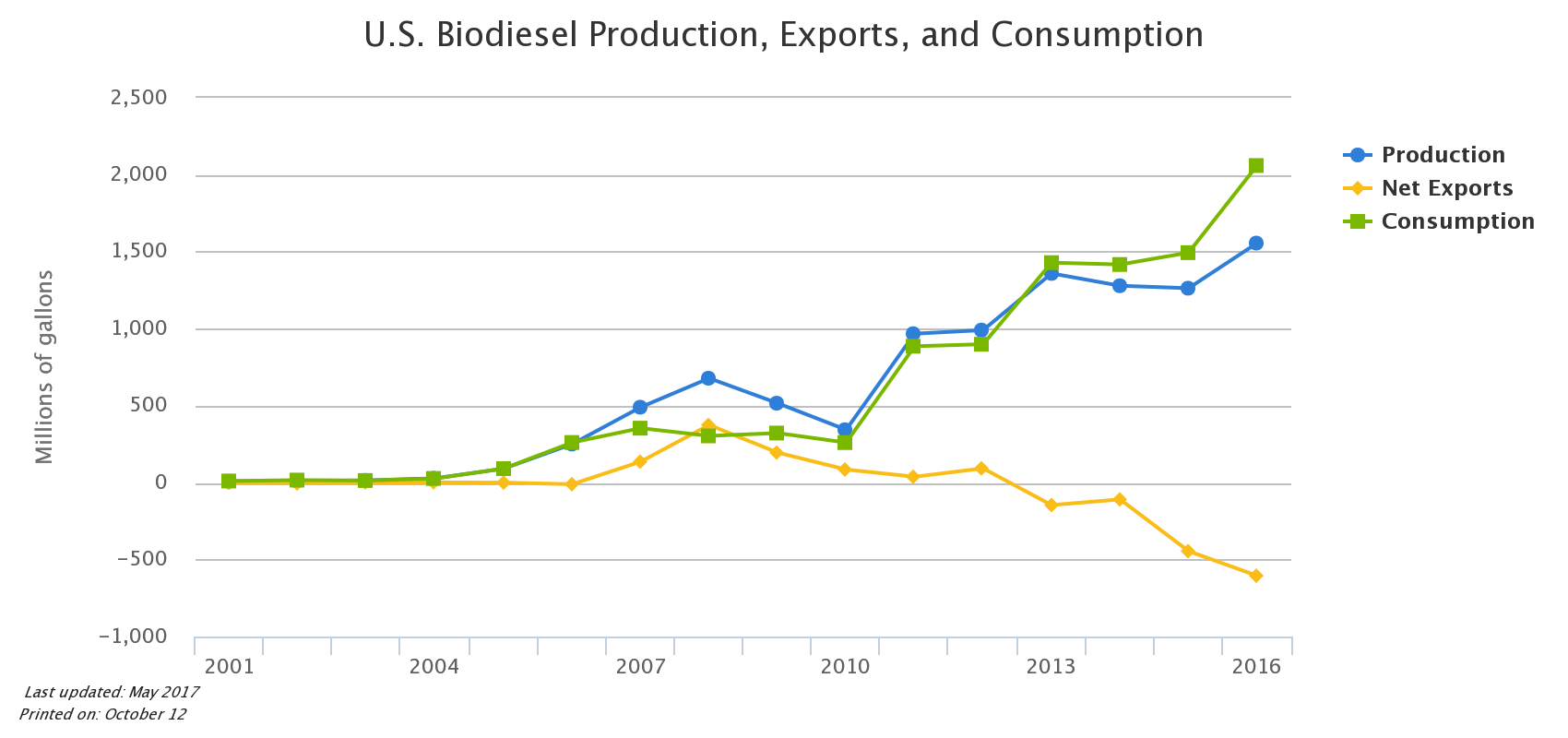

Most of the biodiesel used today is made in the USA. Therefore the use of biodiesel boosts the local economy. Over 1.6 billion gallons of biodiesel was produced domestically in 2016 and that number is increasing.

Find more about this in this DOE's alternative data center website

80% of the whole soybean is meal. The meal contains 45% protein used as food and feed. More biodiesel production translates to more oil production and four times as much of meal production. This increases the food and feed supply. The data does not support the Food Vs. Fuel Argument for biodiesel. Please read this technote Biofuel and Indirect Land Use Change and study about this issue on Biofuel impact on food prices index and land use change.

Lubricity is defined as the ability of a fluid to minimize the degree of friction between surfaces in relative motion under load conditions. Low lubricity means rapid engine wear and tear. Even 1% of biodiesel adds enough lubricity in fuel and enhances engine performance.

The need for diesel fuel lubricity has been recognized for many years. Most early concerns focused on the use of #1 diesel fuel in place of #2 diesel fuel under cold weather conditions. Higher wear rates with #1 diesel fuel would be aggravated by #1 diesel fuel's lower viscosity. However, when the U.S. Environmental Protection Agency mandated that the sulfur content of on-highway diesel fuel be lowered from 5000 ppm to 500 ppm in 1993, fuel lubricity captured national attention.

Further reductions in fuel sulfur levels imposed by the EPA to 15 ppm were found to make the fuel lubricity even worse. The addition of small amounts of biodiesel (0.25% to 2%) to diesel fuel has a dramatic effect on the lubricity of that fuel. Pure biodiesel and high level blends have excellent lubricity. Please look into our collection of literature about biodiesel lubricity

Use of biodiesel needs no engine modification. Biodiesel blends up to 5% meet the same specifications as diesel fuel. Source: Alternative Fuel Data Center